Meats and Sausages

Drain Water Pipe Smoker

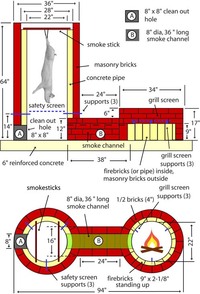

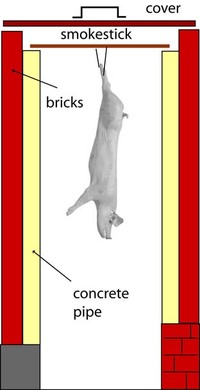

The majority of masonry smokehouses are rectangular in shape; thus the meat smoker below looks different and more original. The firebox design is based on a round fire pit which is popular in Argentina. A round fire pit is a very practical, visually pleasing and inexpensive solution for confining hot fire in a designated area. A drain water pipe is used to build the smokehouse. Such pipes are lying around wherever new housing projects are built in developing areas. They come in 10' length and are made of reinforced concrete about 3" thick. Inside diameters vary from 12" to 40" in 2" increments. Due to its length and size, an average pipe weighs about 800 lbs, its transport is one of the most difficult parts of a project. The pipe will have to be cut down to size, and the openings for a smoke delivery channel and clean-out access have to be made. That can be accomplished with a portable motorized saw with a 12" diamond blade. A saw can be rented out or a paving contractor can perform the service.

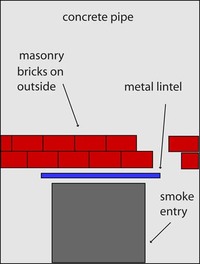

When cutting a pipe down to size the cut section can be saved to be used as an inside part of the fire pit, although an opening will have to be made for the smoke delivery channel. This way we can eliminate laying down the fire bricks. It is recommended to place masonry bricks on the outside of the fire pit and the smoker for a more elegant look.

This smoker has many advantages:

- Due to the smoker's round shape, smoke flows evenly inside without creating blind pockets.

- Smoker has very good natural insulation due to its very thick walls.

- Neither a meat loading door nor a firebox door are needed.

- It is very simple to build, there are no precise measurements or difficult hardware or hinges to install.

Due to its massive weight a solid 6" reinforced concrete foundation has to be poured down. Using concrete pipes for making smokehouses is quite common.

In place of smoke channel "B" the round pipe 6" in diameter may be installed.

Description

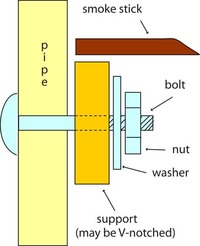

The beauty of this design is that both a smoker and a grill use the same fire pit. The amount of smoke or heat going into the smoker is adjusted by moving burning wood towards or away from the entrance to the smoker. This is accomplished by burning an open fire right on the concrete foundation floor. A metal grate with short legs can be placed in the fire pit, and the wood will burn faster and at a higher temperature having an extra supply of fresh air from below. The fire pit can be covered with a metal cover that will send all available heat to the smoker. Neither the smoker nor the fire pit employs any doors which greatly simplifies construction. Instead, a round metal cover is placed on top of the smoker. By moving this cover a smoke draft control is established. A masonry drill can drill through the pipe wall, and smokesticks can be inserted into holes. This, however, is inconvenient when loading many sausages, and it is impossible to hang a long rope sausage. A more professional solution is to install smokestick supports that allow for loading smokesticks outside. Supports for a safety screen can be drilled right through the concrete pipe wall. It is a wise precaution to install a safety screen to prevent the possibility of meats falling down on the floor during smoking.

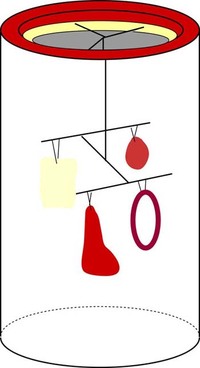

A good idea is to make the outside bricks about 2" longer than the pipe. Metal rebars may be used as smokesticks, and the cover will sit on top of the bricks above them. A crossbar with three arms separated by 120 degrees can be constructed and will permit to hang more meats in the lower part of the smokehouse.

Grill/Fire Pit

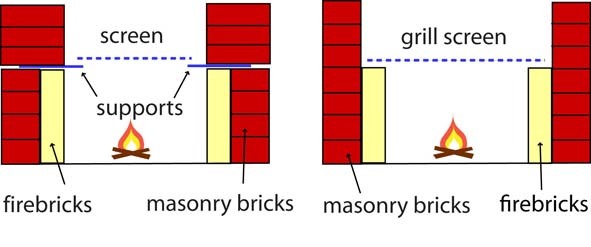

A grill is nothing more than a metal screen suspended on supports inside of the fire pit. Such round screens are available in standard sizes at all department stores.

Grill screen support. Left-three metal supports embedded between bricks and spaced equally every 120 degrees. Right-firebricks are used as grill screen support. The easiest approach.

The supports can be 4" long pieces of rod or flat metal and should be inserted into damp mortar between the bricks. They can go on top of vertically standing firebricks, which determines the height of the screen, which is 9". The screen is surrounded by an additional 8" of bricks and that will confine heat in the grill area. When cutting the pipe down to size, it is a good idea to cut another section for the inside wall of the fire pit, providing that the fire pit and smokehouse are of the same diameter. Remember to also cut an opening for the smoke channel. This way the smoker and the fire pit will be of the same diameter. This is not a rule and the fire pit can be made wider than the smokehouse. The smoker is top loaded, and at first, it may seem too high and awkward, but the top of the smoke delivery channel "B" serves as the 11" high step ladder, and loading the smokehouse becomes quite easy.

Using the smoke delivery channel as a step ladder is the reason why the smoke sticks should be installed perpendicular to the smoke delivery channel. This provides a strong grip and facilitates their insertion or removal. There is a 8" x 8" clean-out access "A" to facilitate cleaning the smoker or recovery of the fallen items. An electric heating element can be inserted through this hole when the wood is in short supply. It is a very unusual-looking smoker which works very well.

There is no need to buy sawdust or wood chips. Logs of wood are used and smoking can continue for days or weeks with little supervision. If it stops at night, it can be very easily re-ignited the following morning.

The following photos provided courtesy Mr. Peter J. Van Brussel from Ohio:

The above information is reprinted with permission from Meat Smoking and Smokehouse Design.