Meats and Sausages

Can Sealers

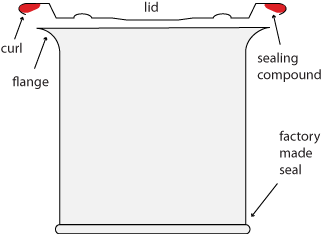

Can sealer hermetically seales cans. The process of attaching the can end (lid) to the can body is called double seaming. This seam is formed by mechanically interlocking the outside end of the lid known as the "curl" with the top part of the can body known as the "flange."

Curl and flange form double seam.

Double Seam

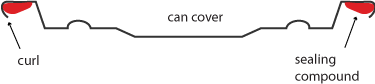

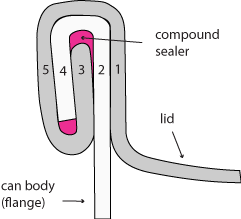

A double seam is formed by joining the body of the can with the lid, which in trade is usually referred to as the cover or the end. The body flange and the curl of the lid interlock together and form a strong mechanical joint. However, this joint, although strong is not yet airtight and cannot be considered to be a hermetically formed closure. A sealing compound is attached to the curl of the lid. Compressing the lid and can body together forces the soft compound sealant to flow and fill any little spaces that might be present in a double seam and the combination of a double seam and the dealing compound makes a hermetically (airtight) formed closure. The amount of the compound sealer and its composition depends on the style of container and the method of sterilization. Each double seal consists of five layers of metal interlocked together: three from the lid and two from the body of the can.

A cover carries a sealing compound inside of its curl.

Curl and flange form double seam.

A double seal is a strong mechanical structure containing five layers of metal together, three layers of the lid and two layers of the can body.

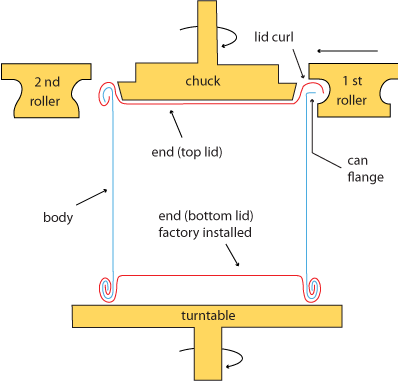

Basic parts of a sealer.

Each sealer or "seamer machine" (industry name) has a:

- Base plate (turntable) - provides support for the can body.

- Seaming chuck - snugly holds the top of the can (lid) and acts as a support surface for the pressure of the rollers.

- A set of operation rollers - the first roller interlocks the lid with the body of the can. The second roller tightens and irons out the seam.

Sealing is a critical operation in the can processing. It must protect the contents of the can during thermal processing, and it must isolate canned food from microorganisms and air during storage.

Ives-Way sealer. Chuck, 1st and 2nd roller and turntable. This turntable is free spinning and so are the rollers. The manual crank turns the chuck and the chuck turns the table (through the can).

Methods of Sealing (Principles of Sealing Cans)

There are two sealing machine designs:

- Can spin - the can is turning, the chuck is stationery.

- Can stand still - the chuck and the can are spinning.

Our discussion is limited to the "can still" design as the sealers designed for home market are based on this principle.

Sealing cans involves three operations: