Meats and Sausages

Distillation Reflux Principle

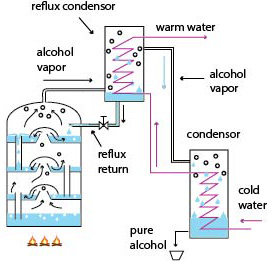

The fractionating column can only work when the plates are holding a boiling mixture of water and alcohol. Drain the liquid away and the column becomes an empty pipe. That is why a part of freshly made alcohol is continuously redirected towards the column where it flows down on the top plate. Depending on a design and the purity of alcohol we want to obtain, the ratios vary, but about 2/3 of alcohol is re-supplied towards the column and 1/3 towards the storage. After all, the reflux alcohol is not being wasted but rather recirculated over and over again. Commercial producers use two condensers:

- Reflux condenser

- The main condenser

Reflux principle

Both condensers are cooled with water which can flow first towards the main condenser and then through the reflux condenser, or both condensers can have separate cooling systems. Operation of the reflux condenser is controlled with cooling water. Some of the alcohol vapor that enters the reflux condenser will immediately liquefy and drip down to the bottom of the condenser. From there a part of liquid alcohol is redirected to the column to keep the plates flooded. Uncondensed vapor will flow towards the main condenser where it will liquefy. This extra condenser may be considered another distillation step and another plate in the column, so obviously a two condenser design will make even purer and stronger alcohol. When the level of liquid in the top tray rises too high, it overflows to the tray below. The trays must always be covered with liquid, otherwise the alcohol vapor will rush without resistance through the column into a condenser and we will end up having a simple pot still. To keep trays filled with liquid a large part of distillate is redirected back from the condenser to the top tray in the column. The remaining part of distillate is taken for bottling. The downflowing reflux liquid provides cooling and condensation of upflowing vapors thereby increasing the efficacy of the distillation tower. The more reflux and/ or more trays provided, the better is the tower's separation of lower boiling materials from higher boiling materials.

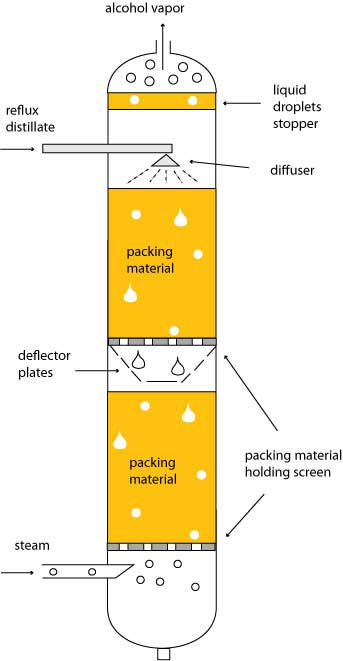

Reflux Columns With Packing Material

Reflux columns are much simpler to build and this design performs very well in smaller diameter columns. Such a column is filled with a packing material which rests on a supporting screen. The reflux distillate flows on top of the packing material through a diffuser that atomizes liquid into a fine spray. It may be compared to a showering head. This also helps to eliminate "channeling" the tendency of the liquid to flow down using walls. On the way out the alcohol vapor hits the metal screen or another layer of packing material which stops alcohol droplets and lets only vapor out. A perforated metal plate is often placed on top of packing material to prevent smaller particles from being kidnapped by alcohol vapor.

Reflux column with packing material.